Power Sector

DATA PKT Aviation offers a cutting-edge solution for inspecting transmission power lines using drones, revolutionising the traditional methods with enhanced efficiency and accuracy. Our comprehensive system employs artificial intelligence and machine learning to automate the entire inspection process, from capturing data to generating analytical reports.

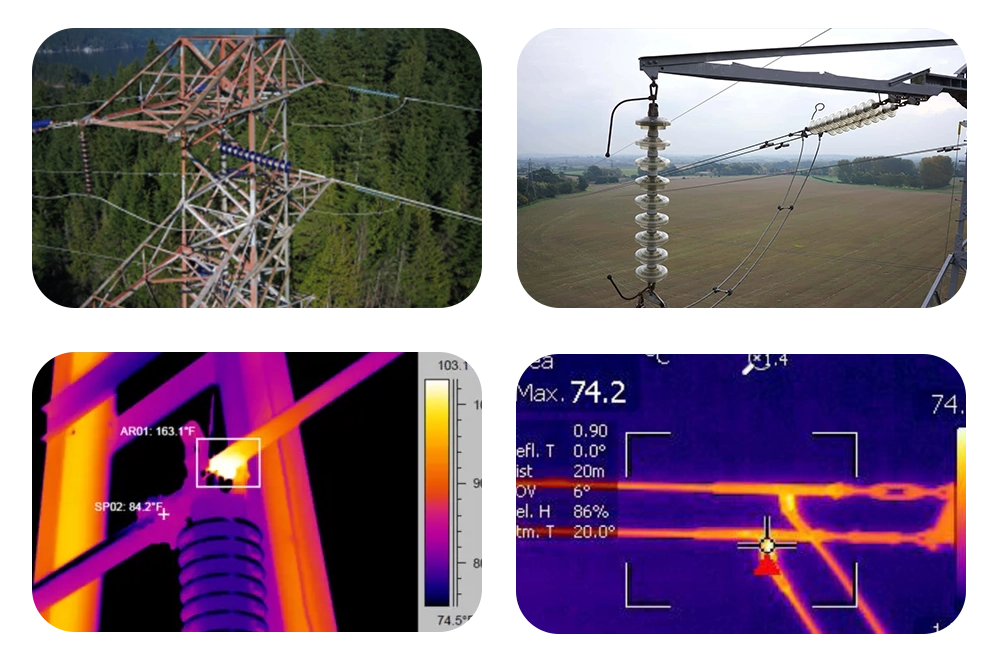

Our transmission line drone surveys encompass a thorough examination of various components, including towers, conductors, insulators, rights of way (ROW), and vibration dampers. By utilising thermal imaging cameras mounted on drones, we can detect hotspots caused by issues such as loose connections, load imbalances, and corrosion, which could lead to temperature variations and potential hazards.

The integration of AI technology enables automatic detection of significant irregularities in transmission lines, allowing our clients to receive actionable insights through detailed analytical reports. With this advanced approach, a single drone crew can cover extensive regions, inspecting approximately 10-15 pylons per day. This streamlined process minimises expenses, reduces manpower requirements, and enhances the overall safety and reliability of electrical transmission systems.

Deliverable: We provide site topography survey reports with grid installation feasibility, Higher-resolution visual images of grids with Detailed Project Reports.

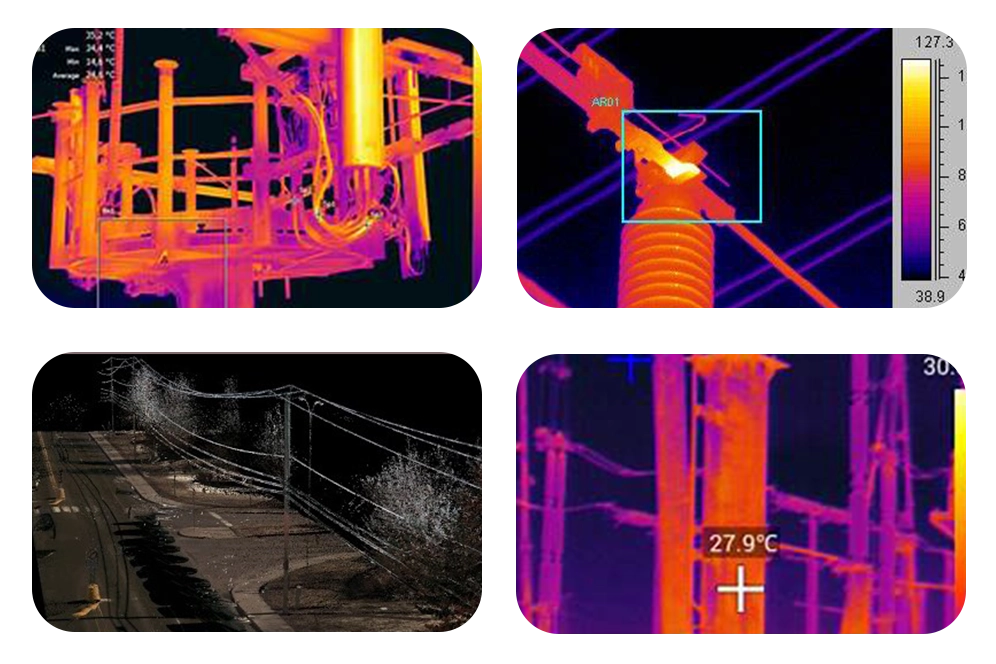

Electricity is transferred from the transmission system to the final user via distribution lines. Ordinarily, distribution voltages are moved across short distances in a range of 4 kV to 35 kV. Aerial and Thermal Surveys of distribution lines is a service provided by DATA PKT using AI/ML-integrated drones, generating accurate, inexpensive, useful, and efficient data.

DATA PKT employs specially created drones that can withstand strong electromagnetic forces and are outfitted with Dual Gimbal systems that simultaneously provide an ultra-high-resolution 360-degree view and thermal images.

In our drone surveys of distribution lines we provide Surveys of pillars, conductors, insulators, ROW(rights of way), span losses, Go switches, Split pins, nut bolts, cross arms and stays of distribution lines.

Drones with artificial intelligence (AI) are employed in distribution lines to estimate demand, analyse the reliability of the state's power plant, and find defects in the smart grid and power systems.

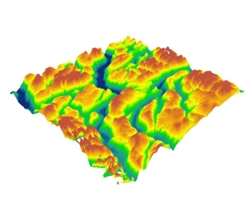

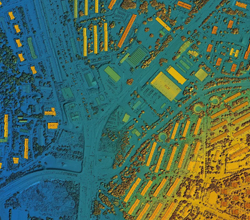

Deliverable: We provide site topography survey reports with electricity pillar installation and condition feasibility, Higher-resolution visual images of grids, poles, and other components. Elevation data, Contour map of the site and 3D Model with cloud point.

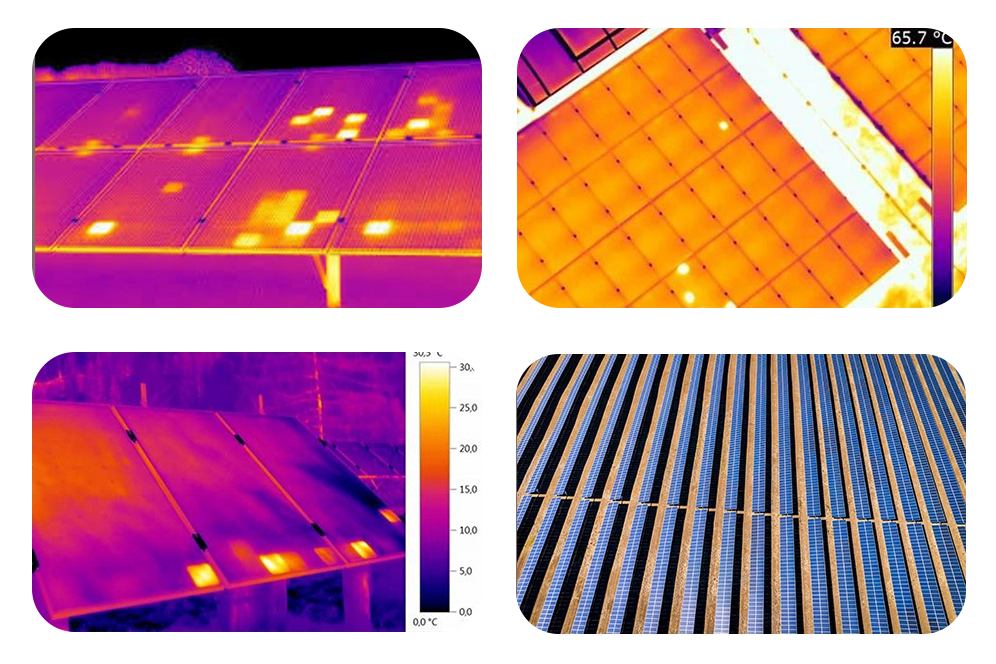

Drones are being used by solar power plants to give an airborne perspective that enables quicker diagnosis of damaged solar panels. Drones equipped with dual-mode high-end thermal cameras and ultra-high-definition video cameras with 16x zoom offer temperature differences and crisp images for quick identification of defective panels, cracks, or shadows. This technology reduces inspection time significantly, allowing for faster maintenance responses and minimized downtime. As a result, solar power plants can maintain optimal efficiency and output.

By utilizing drone technology for solar plant inspections, DATA PKT significantly reduces inspection costs by 30 to 50 percent compared to traditional methods.

Our services provide detailed topological maps and thermograms, identifying issues such as hot spots, cracked panels, and bypass diode failures, enabling prompt maintenance and optimization of solar plant performance.

Deliverables: include geotagged high-resolution visible and thermal infrared images, Orth mosaics with elevation data and AI/ML-based analytics for quick analysis and provide plant efficiency reports.

Drones are becoming a crucial component of managing, operating, and preserving wind farms. Using drones instead of traditional inspection makes inspecting rotor blades simple. We can now identify the inside of the rotor blade thanks to developments in the thermal system. Drones cut the number of man-hours and turbine downtime required for maintenance checks by approximately 75%, with inspection times of 15 to 30 minutes per turbine having been proven.

Wind turbine blade inspection methods include both surface and subsurface techniques. Surface inspections use visual technologies like sensors and drones to detect fractures, erosion, lightning, and bird strikes. Early detection enables efficient corrective maintenance. Sub-surface examinations use non-destructive methods such as thermal imaging, ultrasound, and electromagnetic waves to detect structural faults in the blades' internal structure, such as damaged shear webs and bonding erosion. Internal inspections, which require professionals to physically climb into the blades, are limited due to height, safety, and efficiency limits, leaving a considerable fraction uninspected, particularly in offshore wind farms.

Our cutting-edge technology allows us to effectively inspect a wide range of faults in wind turbine blades.

Deliverables: We provide site feasibility and topography survey reports, Higher-resolution visual inspections, Ortho-mosaic, Digital surface model, Digital terrain model with elevation data, a Contour map of the site and a 3D Model with cloud point.

Drones play a crucial role in enhancing safety and efficiency at nuclear power stations by providing an effective means of managing potential leaks and assessing equipment integrity without exposing personnel to dangerous levels of radiation. Following natural disasters and weather events, such as hurricanes or earthquakes, nuclear power stations may face structural damage or operational disruptions. In these situations, the use of unmanned aerial vehicles (UAVs) for inspections can minimize efficiency losses by 6 to 8%, compared to traditional manual inspections. This is particularly significant considering the potential catastrophic consequences of even minor damage to nuclear facilities.

Unmanned aerial vehicles equipped with specialized sensors and cameras can access areas that are difficult or dangerous for humans to reach, such as rooftops, cooling towers, and reactor containment structures. They can provide high-resolution imagery and data in real-time, allowing operators to quickly identify any issues or anomalies. Additionally, drones can be deployed rapidly, reducing the time required to assess the situation and implement necessary repairs or maintenance activities.

Deliverable: We provide site topography survey reports with environmental impact assessment reports, Higher-resolution visual images, Ortho-mosaic, Digital surface models, Digital terrain models with elevation data, a Contour map of the site and 3D Models with cloud points.

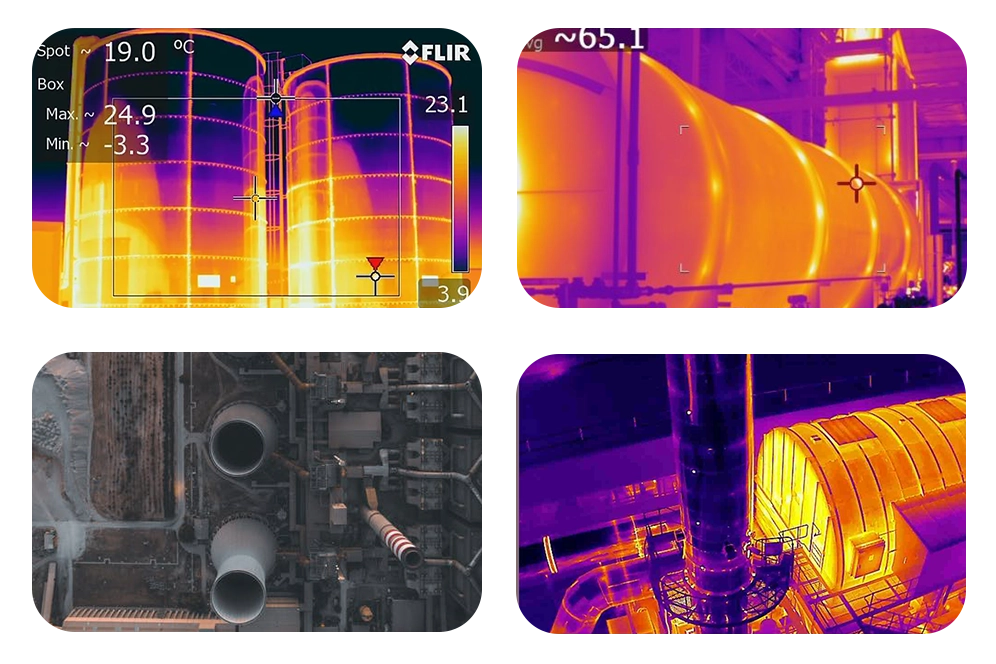

Drone technology has revolutionized inspection processes in thermal power plants, providing efficient thermal surveys of chimneys and monitoring air pollution from by-product gases. DATA PKT offers automated inspection and monitoring of crucial assets such as boilers, cooling towers, pipelines, tanks, and flare stacks. With drones, plant operators can access hard-to-reach areas, identify defects, and assess the structural integrity of equipment more effectively. This proactive approach enhances safety, reduces downtime, and optimizes maintenance schedules, ultimately improving the overall performance and longevity of thermal power plants.

Our AI-equipped drone, equipped with an Ultra High-Resolution camera, plays a pivotal role in power plant maintenance. By identifying potential defects with precision and assisting in gathering vital data, it optimizes efficiency, safety, and return on investment. These drones conduct thorough inspections, capturing detailed imagery of critical components, enabling proactive maintenance and minimizing downtime. With their advanced technology and capabilities, they significantly contribute to lengthening the lifespan of power plants, ensuring continuous operation, reducing costs, and enhancing overall performance. This innovative approach revolutionizes maintenance practices, ensuring the reliability and sustainability of power generation infrastructure.

Deliverable: DATA PKT provides detailed performance reports of thermal plants with Ortho-mosaic, Thermal and Infrared imagery and AI/ML-based analytics to increase the cost efficiency of the power plant.

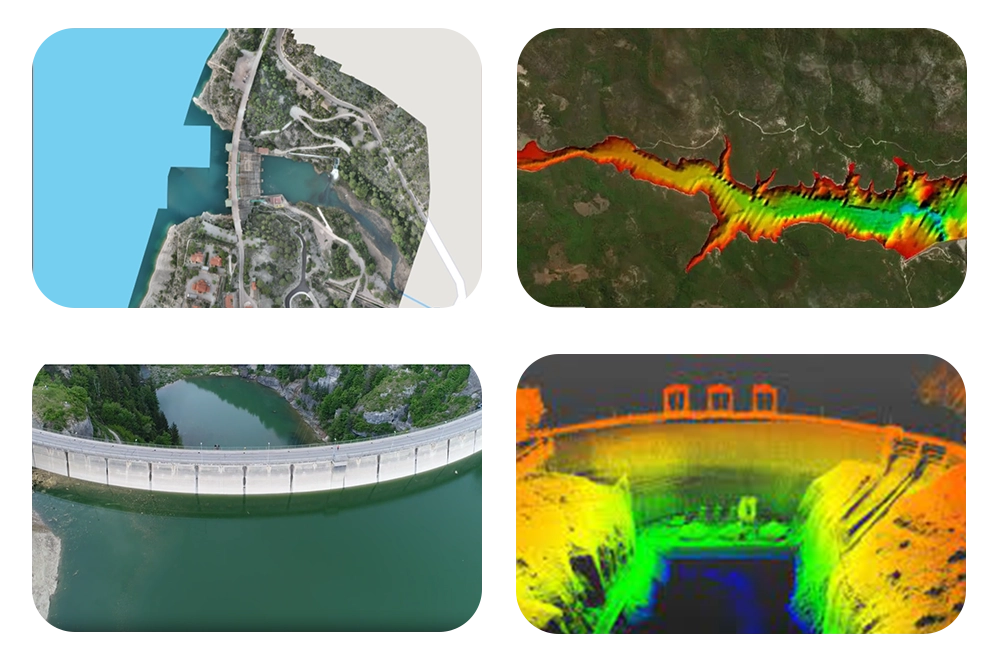

Drone inspections offer the advantage of capturing high-resolution imagery and data, allowing for more detailed analysis of dam structures and identifying potential issues at an early stage. The agility and maneuverability of drones enable them to access hard-to-reach areas, such as steep slopes or areas obscured by vegetation, enhancing the comprehensiveness of inspections. Moreover, the use of drones reduces the need for manual labor and scaffolding, resulting in cost savings and increased safety for personnel. By leveraging cutting-edge drone technology, hydropower facilities can enhance their maintenance practices and ensure the continued security and structural integrity of their dams.

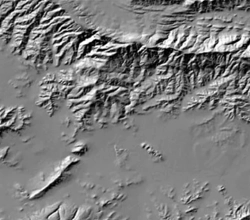

The topographical survey of the dam site, reservoir area, power channel, and tunnel provides essential data for project planning and construction. Surface and subsurface examination yield crucial insights into geological formations, aiding in the identification of potential hazards such as fractures and subsurface features. This information guides the design and construction of spillway gates, tunnels, and surge tanks at penstocks. Moreover, it helps in assessing concrete deterioration, ensuring structural integrity. Accurate data on gate alignments enhances operational efficiency and safety. Overall, comprehensive topographical and geological surveys are indispensable for ensuring the successful and sustainable development of hydroelectric projects.

Deliverable: DATA PKT provides Ortho-mosaic, Thermal and LiDAR imagery in the required format and AI/ML-based analytics for decision-making of plant efficiency.

We offer Detailed Project Reports (DPRs) for the energy sector, providing comprehensive insights and analysis essential for informed decision-making and efficient management of energy infrastructure projects.

We offer Digital Terrain Models (DTMs) tailored for the energy sector, crucial for installing and inspecting plants and transmission pillars. Our precise models enable thorough assessment and planning, ensuring optimal infrastructure deployment and ongoing maintenance within the energy industry.

We offer precise point cloud data for the energy sector, providing detailed 3D representations of infrastructure elements. This information aids in accurate assessments, design optimizations, and efficient decision-making processes for energy projects.

We specialize in producing orthomosaics tailored for the energy sector, providing detailed aerial imagery essential for site analysis, infrastructure planning, and ongoing monitoring. Our high-resolution orthomosaics ensure accurate insights for efficient energy sector development and management.

We deliver Digital Surface Models (DSMs) for the energy sector, essential for planning plant installations and transmission pillar placement. These detailed models offer insights into terrain characteristics, enabling strategic decisions for infrastructure development and deployment.

Employing aerial photogrammetry and videography enriches energy projects with intricate imagery, essential for planning, monitoring, and documenting activities within the energy sector, facilitating informed decision-making and efficient operations.

We offer specialized topographic surveys for the energy sector, facilitating plant installation and transmission pillar placement. Our precise assessments ensure optimal planning and seamless execution, vital for efficient energy infrastructure development.

We offer Digital Elevation Models (DEMs) customized for the energy sector, essential for planning and implementing infrastructure projects. Our accurate DEMs provide detailed elevation data crucial for optimizing site selection, design, and operational efficiency within the energy industry.

We specialize in LiDAR surveys for the energy sector, offering detailed insights essential for infrastructure planning, site assessment, and ongoing monitoring. Our advanced technology ensures precise data collection, facilitating efficient development and maintenance within the energy industry.

We specialize in providing thermal imaging services tailored for the energy sector. Our precise thermal images offer invaluable insights for detecting anomalies, optimizing energy efficiency, and ensuring the safety and reliability of critical infrastructure.

We've covered over 10000 kilometres of energy infrastructure, showcasing our ability to handle projects of any size.

Demonstrates our commitment to comprehensive solutions for pipelines, power lines, and solar farms.

Our experienced team and advanced survey drones enable us to cover over 100 kilometres of energy infrastructure daily.

Emphasises our agility and efficiency in meeting project deadlines and supporting quick decision-making.

Our dedicated GIS experts ensure prompt processing and analysis of drone survey data, delivering insights on or before agreed deadlines.

Highlights our commitment to timely and reliable service delivery, enabling clients to optimize operations proactively.

Our state-of-the-art drone technology offers up to 70% greater accuracy compared to traditional methods.

Provides clients with confidence in making informed decisions for asset monitoring, maintenance planning, and risk assessment.