Mining Sector

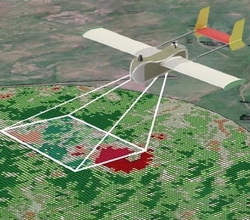

The search for evidence of mineralization in the rocks around is the process of mineral exploration. The primary method creates a geological picture by combining geological information from many sites and projecting it across a larger area. The exploration of new regions rises along with the demand for resources. By the end of 2030, the demand will have increased by 60%.

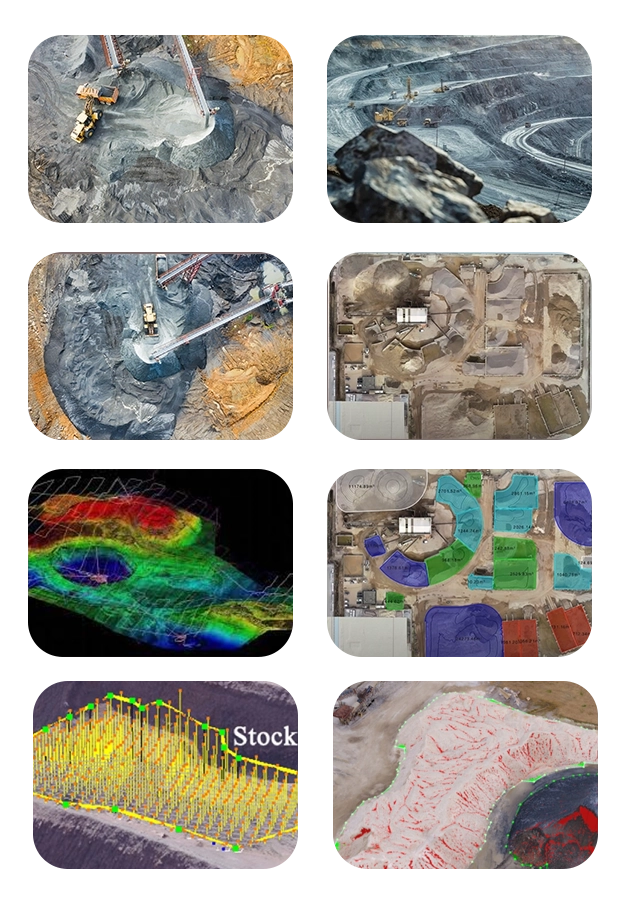

Mining exploration has been revamped via the use of top-notch drones since drone technology has redefined multiple aspects of the mining industry.

Mining exploration has been revamped via the use of top-notch drones since drone technology has redefined multiple aspects of the mining industry. These advanced drones equipped with DATAPKT AI facilitate the establishment of a fundamental image of the region's geology. Each successive stage of work in an area will build on and relate back to this initial stage, leveraging the insights gathered by the drones. This integration of drone technology significantly enhances the efficiency and accuracy of mineral exploration, leading to more effective resource utilization and sustainable mining practices.

Using a drone, DATA PKT assists in optimising the following processes throughout the mining development phase:-

A haul road is a type of road in the mining industry used to transport heavy and bulky materials by haul trucks. It is sometimes referred to as a haulage road or a haul track.

Material hauling accounts for a significant portion of a mine's expenses. A safe transportation system is made possible by well-designed and maintained roads, which immediately cut cycle times, fuel consumption, tyre prices, and overall cost per tonne transported.

Drones are capable of performing a range of activities connected to haulage roads, including precision mapping, time-sensitive land surveys, and quick road inspections. Drones are necessary for the long-term and economic management of transportation infrastructure and road upkeep.

Traditional surveying techniques require careful measuring, planning, and preparation, which adds delay to the data collection process. Drones, on the other hand, can gather all of this data in a very short amount of time. A conventional survey would take 70% longer than one using drones. In addition, as compared to traditional surveys, drone surveys need half the amount of labour.

Most notably in metallurgical or coal mines, tailings dams are a familiar sight. They may cover entire square kilometres and are built of earth. They act as a garbage repository for all the contaminated byproducts of mining activities. When you decide to use a drone to monitor your tailings dam, you instantly cut down on the dangers of surveying staff by cutting the likelihood of people entering unsafe regions by 48%. Drone surveying is possible using just line-of-sight distance. There is no longer a need for them to remain so near to the area's harmful chemicals and dust.

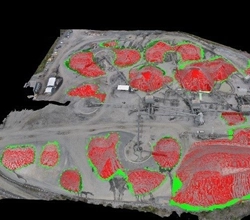

Stockpile management is crucial for minimizing environmental impact and ensuring regulatory compliance in mining and construction activities. By implementing erosion control measures such as proper covering, grading, and vegetation, companies can mitigate the risk of sediment flow from soil stockpiles, preserving nearby waterways and ecosystems. Moreover, stockpile management becomes imperative when dealing with erodible materials, as it helps prevent soil loss, contamination, and potential hazards to surrounding areas.

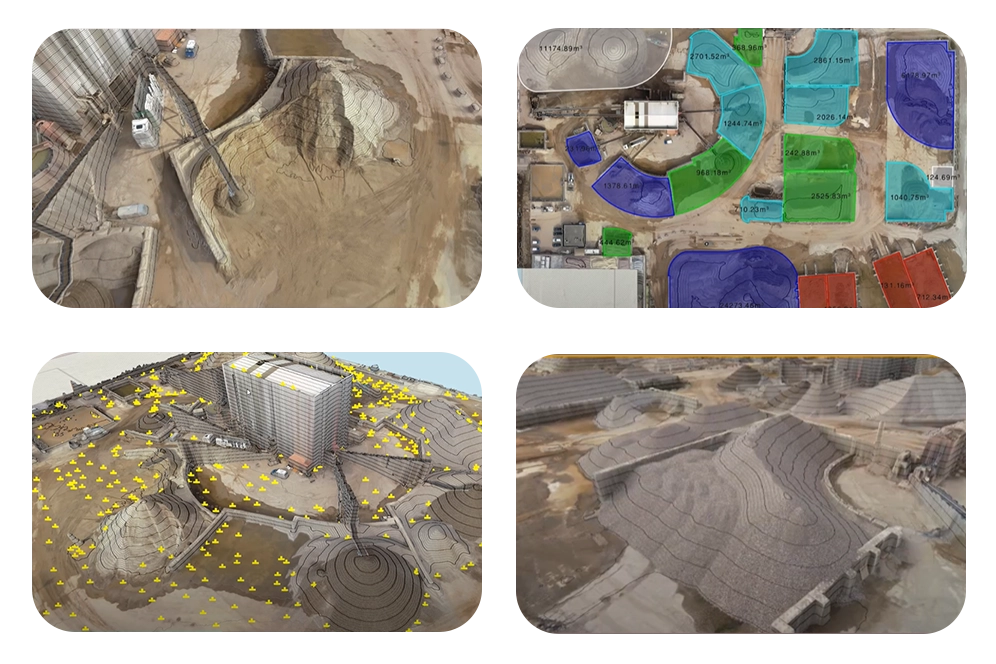

DATA PKT revolutionizes stockpile management by providing comprehensive solutions tailored to the specific needs of miners. Through advanced technology integration, DATA PKT enables transparent operations by providing stakeholders with real-time access to crucial data and analytics. Enhanced inventory management ensures optimal utilization of resources while minimizing waste and redundancy. Real-time quarry monitoring allows for proactive decision-making and risk mitigation, enhancing safety and operational efficiency. Additionally, the use of drones for stockpile evaluation provides accurate volumetric measurements, improving planning and forecasting capabilities. Overall, DATA PKT empowers miners to streamline their stockpile management processes, leading to cost savings, time efficiencies, and sustainable operations.

Reclamation of mined land is the process of restoring it to the condition it was in before mining. When you restore land, you are minimizing the negative environmental consequences of mining. Reforestation and new development are the most typical methods of reclamation.

The most accurate approach to predict how much work is left to do and when reclamation will start is to use a drone, which also aids in tracking extraction progress and material movement. Aerial surveys employing numerous drone flights are the quickest and most reliable way to get this data.

Site Safety Management

Mining sites feature volatile sections with rugged terrain where safety is of the utmost priority. Drones can give precise, high-quality photogrammetric data of mines, which is subsequently turned into digital elevation and surface models. This allows for improved management and task implementation of mining sites

Automated Inspection

Compared to traditional methods, drones with built-in automation assess mining blast sites without endangering human lives. The expense associated with employing significant human resources can be avoided by automating mine inspection using drones. Drones gather an enormous quantity of data that may be used to create othomosaic maps to provide an updated perspective of vast tracts of land.

Site Monitoring And Mapping

DATA PKT drones monitor mining sites with high-quality embedded sensors and give real-time, cost-effective data access. Deep mining tunnels that are inaccessible manually can be monitored by UAVs. This aids in site surveillance and the discovery of any leaks that can endanger human life. Real-time data access guarantees that corrective actions be implemented as soon as problems are found.

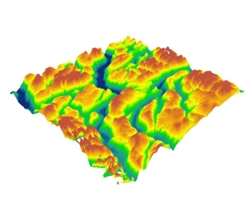

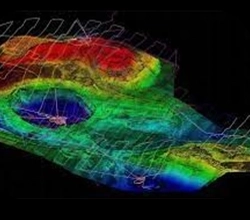

Mine Survey Using Lidar

The use of LiDAR (light detection and ranging) for measuring and inspecting mining pits assists in the creation of precise topographical maps of mining operations. Drones integrated with LiDAR sensors to aid in obtaining precise information about the steepness of embankments and unstable ground foundations. While keeping on-site surveyors secure, drones assist surveyors to navigate topographically difficult areas.

Volume Calculation

Volume calculations are important in mining as it helps in determining the cost and efficiency of machines and mining methods. Traditionally, RTK-GPS systems are required to be installed, the installation can be life-threatening for the miner, therefore Digital terrain modelling(DTM) can be used for volume calculations with the help of Drones.

We deliver Detailed project reports for mining endeavors, leveraging drone surveys to furnish detailed insights into terrain mapping, accurate stockpile volume measurement, and ongoing site monitoring. Our reports ensure informed decision-making and optimize operational efficiency in mining projects.

We offer comprehensive Digital Terrain Models (DTM) derived from drone surveys tailored for mining projects. Our DTM solutions provide detailed elevation data, enabling precise terrain mapping, volume calculations, and site planning to optimize mining operations and support informed decision-making for sustainable resource extraction.

Drones offer rapid and precise volume measurements of mined material stockpiles, including ore, coal, or aggregates. This data is indispensable for efficient inventory management, strategic production planning, and ensuring accurate financial reporting, enhancing operational efficiency and decision-making in the mining industry.

we create orthomosaic for highway construction using drone-captured aerial imagery stitched together using photogrammetry software for comprehensive site visualization and analysis.Orthomosaic imagery from drones enhances highway construction by providing detailed, accurate visual data for planning, monitoring, and quality assurance.

We specialize in delivering Digital Surface Models (DSM) derived from drone surveys specifically designed for mining projects. Our DSM solutions offer detailed terrain mapping, facilitating accurate stockpile volume measurement and strategic site planning to enhance productivity and efficiency in mining operations.

We specialize in aerial photography and videography services using drones for mining projects. Our high-quality imagery and videos offer valuable visual documentation, aiding in project planning, monitoring, and communication for efficient decision-making throughout the mining process

We specialize in providing topographic surveys using drone technology integrated with Differential Global Positioning System (DGPS) for mining projects. Our surveys deliver highly accurate terrain mapping, facilitating precise resource estimation, site planning, and operational optimization to enhance productivity and efficiency in mining operations

We offer blast monitoring and fragmentation analysis services using drones tailored for mining projects. Our solutions provide real-time monitoring of blasting operations and detailed analysis of rock fragmentation, enhancing safety and optimizing productivity in mining activities.

LIDAR surveys for highways yield detailed topographic data crucial for precise route planning, infrastructure design, and safety assessment. This information guarantees the implementation of optimal construction and maintenance practices, enhancing overall efficiency and safety standards.

We specialize in pit and highwall analysis services using drones for mining projects. Our solutions offer detailed inspections of open-pit mines and highwalls, providing valuable insights to ensure safety, assess stability, and optimize operational efficiency.

With extensive experience in the mining sector, we've surveyed vast areas of mining sites, including open pits, underground tunnels, and exploration zones.

Our commitment to comprehensive coverage ensures that we provide actionable insights for all aspects of mining operations, from exploration to production optimization.

Equipped with cutting-edge drones and skilled personnel, we efficiently cover large mining areas, surpassing traditional surveying methods in speed and accuracy.

Our rapid survey capabilities enable mining companies to access critical data faster, facilitating quicker decision-making and operational adjustments.

Our dedicated team of data analysts and geospatial experts ensures efficient processing and analysis of drone-collected data.

By delivering timely and accurate insights, we empower mining stakeholders to make informed decisions that enhance productivity, safety, and environmental compliance.

Leveraging advanced drone technology, we provide precise mapping and monitoring of mining infrastructure, reducing the risk of accidents and optimizing resource utilization.

Our focus on precision and safety underscores our commitment to supporting sustainable and responsible mining practices.