Oil And Gases

This process includes determining possible geographical sites, undertaking surveys, drilling and exploring, and producing crude oil and gas. Drones have the potential to transform this previously time-consuming, manual procedure into an efficient and accurate one in the following ways:

Midstream refers to the process of transporting crude oil and gas obtained upstream through pipelines, barges, or oil tankers for downstream processing and storage. Long pipelines that may exist above ground or underwater, transport issues, or surplus storage, all of which necessitate secure storage during treatment and subsequent transit as needed.

Midstream activities involve transporting crude oil and gas from upstream production sites to downstream processing facilities and storage locations. Infrastructure for midstream operations includes pipelines, barges, and oil tankers, which transport the resources over long distances, above ground or underwater. Secure storage is essential during midstream processes to address transport issues, accommodate surplus storage needs, and ensure efficient treatment and transit of crude oil and gas

Standing at the conclusion of the cycle, downstream serves as a link between oil and gas businesses and end consumers (B2B, B2C & B2G). At this stage, crude oil and raw natural gas are refined to produce end products such as gasoline, jet fuel, heating oil, natural gas, LPG, and other petrochemicals.

As downstream is closest to the supply chain, a significant amount of people and other resources are expended to ensure that the end product is delivered on time and in an environmentally friendly manner. Industrial leftovers must also be appropriately disposed of so that they do not pose a risk to others.

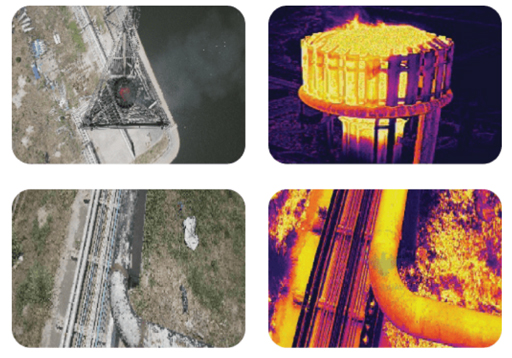

Pipeline Inspections

The inspection of pipelines is one of the most important applications of drones in the oil and gas industry. Drones provide an aerial perspective that allows for comprehensive analysis of pipeline conditions without having to shut down the pipeline. A pipeline inspection drone can spot environmental encroachments, physical damage, corrosion, leaks, and spills.

Gas Flare Stack Inspections

Gas flare stacks are used to burn off waste gases from oil and gas production. Flare stack inspections are critical to maintaining safety and compliance. A drone can capture high-resolution images and thermal imaging to detect leaks, gas combustion, and other potential safety hazards. Through drone inspections, maintenance checks can be done without having to shut down production.

Power Line Inspections

Power lines are critical to the oil and gas industry. Drones can provide effective visual inspections and thermographic imaging to detect damage, wear and tear, and hot spots on power lines. Inspections can be done much more efficiently than traditional methods, reducing costs and minimising safety risks.

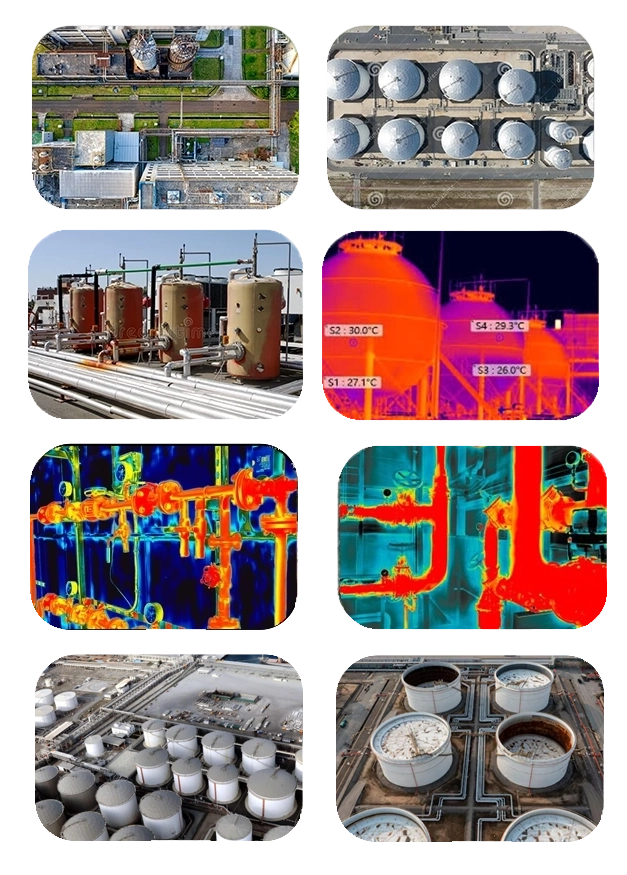

Oil Rig Inspections

Drones can inspect oil rig platforms, derricks, and equipment. With infrared imaging, drones can detect potential equipment failures and cracks that might not be visible from the ground. A drone inspection of drilling platforms increases cost-effectiveness, efficacy, and safety.

Tank Inspections

Tanks are crucial elements in the oil and gas industry. Routine inspections are necessary to detect leaks, surface corrosion, or other damage to the tank. Drones can detect surface level changes, leaks, and other issues that might not be visible to the naked eye. A drone inspection of tanks reduces safety risks and maintenance costs.

With years of experience in the oil and gas sector, we understand the unique challenges and requirements of the industry.

Our team has successfully completed numerous projects, ranging from pipeline inspections to flare stack monitoring, demonstrating our expertise and reliability.

Equipped with state-of-the-art drones and sensors, we offer cutting-edge solutions for aerial inspections, mapping, and surveillance.

Our advanced technology allows us to capture high-resolution images and data, providing accurate and detailed insights into critical infrastructure.

By utilizing drones for oil and gas operations, we minimize downtime and operational disruptions.

Our drone services offer a cost-effective alternative to traditional inspection methods, reducing the need for manual labor and expensive equipment.

Safety is our top priority, and our drone services help mitigate risks associated with hazardous environments.

We adhere to industry regulations and best practices to ensure compliance with safety standards and environmental regulations, safeguarding both personnel and assets.